Introduction

Threaded rods, which are also called studs or all-thread, are the invisible champions of several industries, from very tall buildings to very complicated machines. The high-strength fasteners form a bond, figuratively and literally, between the sectors of construction, automotive, aerospace, and others. India is a country where the production of these rods has been developed to such an extent that now it is like a blending of the old and the new (technology) that produces the products that are of the best quality in the whole world. This piece delves into the process of making threaded rods in India, right from the raw materials to the innovations and challenges driving the industry. Focusing on Threaded Rods Manufacturers India, it's an inside look into the nuts and bolts yes, pun intended of a procedure that's as interesting as it is critical.

Starting Strong: Choosing the Right Raw Materials

All great threaded rods start with the good stuff. The materials selected create the foundation for how solid, robust, or resistant to corrosion the end product will be, and Indian manufacturers take this process seriously to provide high-quality rods for all types of applications.

What's in the Mix

The process starts by picking materials such as carbon steel, stainless steel, alloy steel, brass, or titanium. Each one is good in its way. Carbon steel is a hardworking material strong, cheap, and just right for general construction jobs. Stainless steel, particularly types like 304 or 316, shines in challenging environments, such as coastal areas or chemical plants, because it resists rust. Alloy steel, if it is supplemented with heat treatment, is the best for high-pressure work like heavy machinery. Brass is a top choice for plumbing or electric installations owing to its conductivity and resistance to rust, while titanium light and hardy is the darling of aerospace and medical use. The option hinges on what the rod will be required to accomplish, whether supporting a bridge or being placed within a jet engine, and it's directed by standards such as ASTM A193 or DIN 975.

Ensuring It's Up to Mark

Materials come from trusted suppliers in India’s industrial hubs – Mumbai, Ludhiana, Rajkot – or sometimes from abroad for specialty grades. Before anything else happens, these materials go through the grind. Tests check the chemical composition, like nickel or chromium levels in stainless steel, to ensure it won’t corrode. Tensile strength tests confirm it can take the load, and carbon steel gets a once-over to ensure it welds properly. This focus on quality at the beginning keeps defects at bay and ensures the rods are built to last.

Shaping the Rod: The Manufacturing Process

Raw material is transformed into threaded rods through a multi-stage process that requires precision at every step. Indian manufacturers employ a combination of traditional methods and contemporary machinery to achieve perfection.

Rolling and Drawing the Base

It begins with hot rolling, where raw material billets are rolled in at about 1,200°C and driven through rollers to create cylindrical rods of considerable length. This process gets the diameter even, paving the way for the next step. For those rods requiring a bit more precision, there is cold drawing. In this process, the rods are drawn through a die at room temperature, precisioning their size and smoothing the surface. Cold drawing also toughens the rods by work hardening, a process that is wonderful for high-tensile applications such as building structural supports.

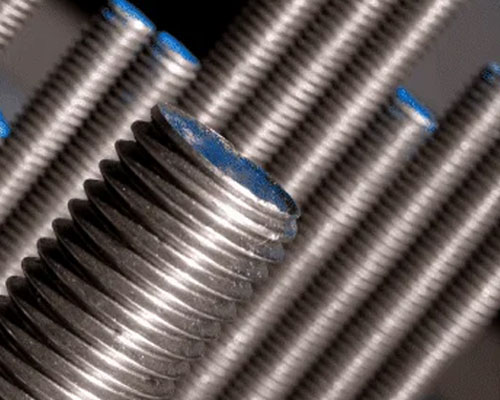

Threading: Where the Magic Happens

The soul of a threaded rod is its threads, and in India, thread rolling is the most popular method. This cold-forming process presses rods between two dies impressed with thread forms, forcing the metal without removing it. The outcome? More resilient threads approximately 20% stronger than cut threads since the grain structure becomes compressed. It's also accurate, meaning threads fit a glove on nuts and other fasteners. Suppliers provide threads in metric sizes (M6 to M48) or imperial (1/4" to 2"), either Class-1 for general use or Class-2 for heavy-duty use.

Toughening Up with Heat

To further strengthen rods, heat treatment comes in. Alloy steel rods, for instance, are heated to 850–900°C, quenched in oil or water to harden, and then tempered at 400–600°C to reduce the brittleness but preserve the strength, ideal for high-pressure applications such as oil refineries (consider ASTM A193 B7 grade). Stainless steel rods might be annealed instead, which relieves internal stresses and increases corrosion resistance, with them then being prepared for adverse environments.

Finishing Touches for Longevity

The last step is surface finishing, which guards rods and makes them appear good. Polishing creates a smooth, shiny surface, while galvanizing immersing rods in melted zinc applies a corrosion-resisting coat, perfect for India's wet coastal environments. Lighter protection is provided by other options, such as zinc plating or chromate, and plain finish rods serve in controlled environments. The finish relies on where the rod's destined galvanized for bridges, polished for machinery, etc.

Maintenance of Quality: Testing and Standards

There can be no compromise on quality in the production of threaded rods, and Indian manufacturers leave no stone unturned to make their products quality-conscious if used domestically or exported overseas.

Testing Every Possible Angle

Every batch of rods undergoes a series of tests. Tensile strength tests determine if they will carry heavy loads. Hardness tests (Rockwell or Brinell) evaluate the durability of rods. Thread conformance is established using go/no-go gauges. Non-destructive tests like ultrasonics will detect if there are other flaws in the rods. If rods are galvanized, they will undergo a salt spray test to ensure the zinc protective coating, which is normally greater than 50 microns, has performed correctly against rust. All rods received markings with their grade and size, batch numbers for traceability, and developed specifications codes, including DIN 976 or ASTM A193.

Meeting Global Benchmarks

Top Threaded Rods Manufacturers India follow very strict guidelines and comply with certifications like ISO 9001:2015 that relate to the quality management system tier and UL certifications, which are applicable to special cases such as fire sprinkler systems, etc. Varmora Forge, located in Gujarat, is an example they have the most modern testing facilities along with accreditation certificates that make their rods accepted in over 85 countries, including the UAE and the USA. Their zeal for quality is the reason why Indian goods are holding their place in the global market.

Where They Shine: Applications Galore

Threaded rods are ubiquitous, reflecting their quality in all spheres due to the ability of Indian producers to adapt to diverse requirements.

Construction and Infrastructure

In construction, threaded rods are used as anchors for concrete beams, or they can be the ones that hold an HVAC system up, or they can be the ones that secure a false ceiling. Galvanized rods are the most common choice for bridges because they can resist rust, while high-tensile rods (like Grade B7) are the ones that carry the weight of skyscrapers. Big projects like the Delhi-Mumbai Industrial Corridor rely on these rods extensively for structural strength.

Industrial and Mechanical Applications

Alloy steel rods provide a solution to the high-pressure and corrosive environments of pipelines and refineries in oil and gas. Engine components and chassis in the automotive industry utilize stainless steel rods due to their strength and smooth surface. Indian manufacturers supply precise requirements from these industries.

Specialized Applications

Titanium rods excel in the aerospace sector, employed in aircraft structures due to their strength and light weight. In the medical field, they're designed into orthopedic implants due to their biocompatibility. Brass rods, being conductive, play a crucial role in electrical grounding systems as they provide safety and dependability.

Obstacles to Overcome: Industry Issues

Despite its success, the threaded rod business in India also has some challenging obstacles it needs to overcome.

Managing Price Fluctuations

Steel prices ride a rollercoaster due to global supply deficiencies or trade restrictions. Import tariffs on specialty alloys come hard, too. Producers offset this by tying up long-term arrangements with local vendors or recycling scrap metal to maintain low costs.

Finding Skilled Hands

India is loaded with workers, but the situation is quite a bit different when it comes to skilled technicians who can use advanced tools like CNC machines or thread rollers. The available workforce is very limited. Companies are solving the problem by collaborating with technical schools and implementing training programs to create a strong workforce.

Going Green

High-energy processes, like hot rolling and galvanizing, are affected as they are facing Indian environmental regulations that are more stringent. Producers are changing over to energy-saving equipment, such as electric furnaces, and also trying out environmentally friendly coatings like zinc-aluminum, which can keep them within the allowed limits, without losing the quality of their products.

Making Progress: Technologies in Action

Indian manufacturers aren't idle instead, they're adopting new technology and sustainable techniques to remain competitive.

Automation for Precision

CNC threading machines and robotic arms to handle materials are accelerating production and reducing errors. Industry 4.0 devices, such as IoT sensors, monitor production via real-time monitoring, identifying problems before they happen. Laser-based thread inspection, for example, guarantees precision to a micron.

Greener Manufacturing

Sustainability is a major area of emphasis, and solar furnaces and recycling water in galvanizing mills reduce the environmental footprint. Recycling of scrap metal not only is cost-saving but also is in line with worldwide green objectives, which makes Indian rods more attractive overseas.

Tailored Solutions

Specialty rods, such as double-end studs with blended threads, are breaking into niche markets such as the Middle East and Europe. These niche products, utilized on such items as adjustable pipe hangers, demonstrate India's capability in responding to distinctive requirements.

The Big Picture: Market and Competition

India's industry of threaded rods is a worldwide giant, with Ludhiana, Mumbai, and Rajkot being the centers that power production. India is a preferred destination for sourcing with low labor costs and easy availability of raw materials.

Going Global

Exports to more than 85 nations, particularly the Middle East, Africa, and North America, are flourishing due to infrastructure development. Galvanized rods are in vogue in the UAE for construction in harsh environments, and high-tensile rods cater to North American oil projects.

Homegrown Demand

India's quick urbanization, spurred by initiatives such as Smart Cities and metro rails, maintains local demand strong. The clean energy industry wind turbine bases and solar panel supports come to mind is another giant driver. Fabricators are ramping up to keep up.

The Road Ahead: Bright Prospects

Technology, demand, and exports are leading the way for India's threaded rod business in the future.

New Trends

Precise fasteners required for the prefabricated parts of modular construction are opening up new opportunities. In aerospace and automotive, titanium, which is a light material, is gaining popularity, thus pushing manufacturers to come up with new ideas. The same goes for AI-powered quality control, which includes tasks such as predictive maintenance.

Government Boost

Programs like Make in India and Atmanirbhar Bharat are not only encouraging local production but also reducing dependence on imports. The industry's green subsidies and improved logistics, for example, freight corridors, are like a boost in its step.

Conclusion

India's threaded rod production is a combination of precision, innovation, and tenacity, making it a world leader. From selecting the appropriate material to weaving flawless threads and assuring supreme quality, Threaded Rods Manufacturers India supply rods that keep the world together. Players like Varmora Forge lead the way, making rods that fuel everything from bridges to jet planes. With automation, sustainability, and customization on an upswing, India's threaded rod market is poised to continue building the future, rod by rod.